Choosing the Right Screw Compressor Service Provider: A Complete Guide

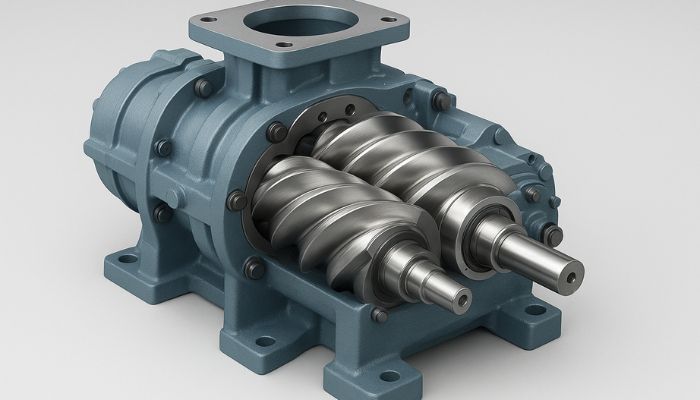

When it comes to industrial operations, screw compressors are the backbone of many processes. Ensuring their efficiency and reliability depends heavily on timely and professional servicing. Choosing the right screw compressor service provider can be challenging, especially with so many options in the market. In this guide, we will walk you through the essential factors to consider before hiring a provider, with insights from Nisha Equipment, a trusted name in compressor solutions.

Why Choosing the Right Service Provider Matters

A screw compressor is not just a piece of equipment—it’s a vital asset that drives production. Any downtime can result in delays, financial loss, and even compromised product quality. This is why selecting the right screw compressor service provider ensures your machines run smoothly, consume less energy, and have a longer lifespan.

Key Factors to Consider

- Experience and Expertise

- Availability of Genuine Spare Parts

- Response Time and Availability

- Customized Maintenance Plans

- Technological Edge

FAQ

Q1. How often should I schedule screw compressor service?

Most compressors require servicing every 2,000–4,000 operating hours, depending on usage and manufacturer guidelines.

Q2. What happens if I delay servicing my compressor?

Delaying service can cause overheating, excessive wear, higher energy consumption, and eventually costly breakdowns.

Q3. Can the right service provider help reduce energy bills?

Yes. Regular servicing ensures your compressor runs efficiently, minimizing energy waste and reducing operating costs.

Final Thoughts

Choosing the right screw compressor service provider is an investment in your business’s efficiency and profitability. With the right partner, you ensure reduced downtime, lower energy costs, and extended equipment life. Nisha Equipment has built its reputation by delivering reliable, timely, and expert services tailored to industrial needs. Contact us Today!

We are always ready to help you and answer your questions